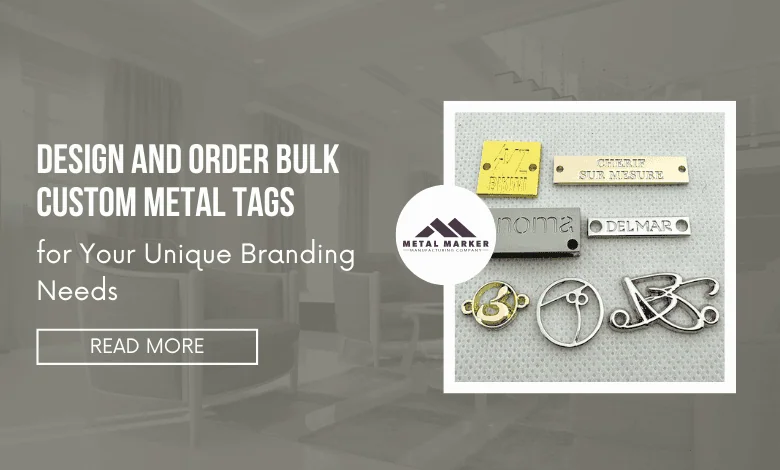

Design and Order Bulk Custom Metal Tags for Your Unique Branding Needs

Exploring the Fascinating World of Metal Tags

The Historical Significance of Tags in Branding

Tags have been around for centuries, acting as a key component in the branding infrastructure of various products and industries. Historically, they served not only as identification markers but also as endorsements of quality and authenticity. Ancient civilizations, such as the Egyptians and Greeks, utilized tags to label goods, often crafted from leather or metal to showcase a merchant’s branding. In medieval Europe, the introduction of more sophisticated production techniques allowed for metal tags to carry intricate designs, indicating not just ownership but also cultural significance and values. As commerce evolved, tags transitioned from mere identifiers to critical tools for conveying brand narratives. The rise of consumerism throughout the 19th and 20th centuries firmly established tags as an essential element in marketing, providing brands a way to differentiate from competitors while building a tangible connection to customers.

Types of Metal Tags: From Anodized Aluminum to Stainless Steel

When it comes to choosing metal tags, brands are greeted with a diverse palette of materials, each offering unique properties that cater to different needs and aesthetics. Anodized aluminum tags, for instance, are lightweight yet robust, making them popular across many sectors, including retail and industrial manufacturing. They come with the additional benefit of a vibrant color range, achieved through an electrochemical process that enhances both durability and visual appeal. On the other hand, stainless steel tags boast unparalleled resistance to corrosion and high wear. This makes them a favorite for applications requiring longevity, such as outdoor equipment or machinery. Other material options include brass, offering a classic and elegant aesthetic, and zinc, known for its economic viability without compromising too much on durability. Selecting the right type of metal tag directly correlates with the intended use, environmental conditions, and overall brand identity.

Why Metal Tags Stand Out: Durability Meets Aesthetic Appeal

In a market saturated with options, metal tags distinguish themselves through a harmonious blend of functionality and style. Their innate durability means they can withstand harsh environmental factors, from extreme temperatures to moisture, ensuring brand longevity. Unlike paper or plastic alternatives that might wear out quickly, high-quality metal tags retain their integrity even under demanding conditions. Beyond durability, their aesthetic appeal is undeniable. Often reflecting a premium quality, metal tags can be styled with custom engravings, vibrant colors, or polished finishes that attract attention. They speak volumes about a brand’s commitment to quality, elegance, and excellence. The tactile nature of metal also enhances customer perception; they are more likely to view a product as valuable when it comes with a well-crafted metal tag, reinforcing the brand’s image in the consumers’ minds.

Unleashing Creativity: Customization Options for Metal Tags

Design Elements that Capture Your Brand’s Essence

Customization is where metal tags come alive, offering brands the opportunity to encapsulate their essence in every piece. From your logo to unique motifs that signify your brand’s ethos, customization allows for limitless creative expressions. The integration of typography plays a vital role as well; the choice of font can evoke different emotions elegant serif fonts may suggest sophistication, while bold sans-serif options can convey a modern, innovative edge. Shape and size are equally crucial; round tags may denote a soft, approachable brand, while rectangular tags might communicate a sense of reliability and structure. Additionally, including symbols or brand colors that resonate deeply with your audience can create immediate recognition and recall. Creativity in design shouldn’t just be visually appealing; every element should stir curiosity and connect with the intended audience on an emotional level, ultimately translating into brand loyalty.

Engraving vs. Printing: Choosing the Right Method for Your Tags

When it comes to customizing metal tags, the method of application significantly affects the final outcome. Engraving offers a feeling of permanence; it involves carving directly into the metal, which not only provides a sophisticated look but also ensures that the text or designs will last over time without fading or chipping. This process is particularly effective for logos or intricate designs that require depth. Conversely, printing is a versatile method that allows for vibrant colors and detailed graphics but may be subject to wear over time, depending on the ink and coating used. Additionally, printing can accommodate gradient designs and complex artwork that are beyond the scope of traditional engraving techniques. Hence, choosing between engraving and printing hinges on the brand’s aesthetic choices, budget considerations, and expected wear and tear from usage.

Color and Finish: How to Make Your Metal Tags Pop

Color and finish are instrumental in making metal tags stand out. The right hue can resonate deeply with consumers, often influencing their perception of a brand. Anodized aluminum, for example, can be coated in a variety of colors, allowing brands to present their personality vividly. Matte finishes tend to impart a modern, understated elegance, while high-gloss finishes may give off a luxurious, premium feel. Additionally, the use of surface texturing such as brushed or patterned finishes can add depth and sophistication to the design. Consideration should be given to how these elements work together with the logo, theme, and intended product to ensure cohesive branding. A thoughtful approach to color and finish not only enhances visual interest but can also elevate a brand’s market positioning and appeal.

The Manufacturing Process: Bringing Your Designs to Life

From Concept to Creation: The Journey of Your Custom Tags

The manufacturing journey of custom metal tags is a fascinating process that encompasses various stages, from initial concepts to the final product. It begins with a detailed design brief that outlines the brand’s vision, specifications, and functional requirements. This stage is crucial; engaging with experienced designers can refine ideas into workable visual elements that align with production capabilities. Once the design is finalized, the production process kicks off, involving CNC machining or die-cutting to shape the metal tags to the specified dimensions. If engraving is selected, it occurs at this stage, followed by any coloring and finishing applications. A prototype may be created for final approval before moving on to bulk production, ensuring that all details meet the brand’s quality standards. This complex assembly of craftsmanship and technology guarantees that the tags are produced to the highest quality, synonymous with the brand itself.

Understanding Bulk Ordering: Economies of Scale and Quality Control

Bulk ordering of bulk custom metal tags comes with its advantages, primarily economies of scale. When produced in large quantities, the cost per unit usually decreases, making it a more viable option for brands needing larger inventories. Bulk production often hinges on streamlined processes, which can lead to faster turnaround times without compromising quality. However, navigating this process requires diligence in overseeing quality control measures. Brands should establish clear specifications and conduct routine checks throughout the manufacturing process. This includes reviewing samples at various stages to ensure that color, finish, and overall quality meet expectations before full production runs. Effective communication with manufacturers can mitigate risks associated with bulk production, affirming that the final products accurately reflect the brand’s identity and standards.

Meeting Deadlines: How Fast Can Your Tags Be Delivered?

Time considerations are paramount when it comes to custom metal tag production, especially for businesses with rigorous timelines for marketing campaigns, product launches, or events. While the manufacturing timeline can vary based on the complexity of the design and the volume ordered, many manufacturers can expedite the process if necessary. Standard lead times usually range from a few weeks to a couple of months, but options for rush orders often exist. Choosing the right production partner who understands your urgency can significantly streamline this process. Moreover, facilitating prompt approvals during the design phase and maintaining open lines of communication can help mitigate unexpected delays. Anticipating your needs and planning ahead are key strategies in ensuring that your metal tags are delivered on time, keeping campaigns and brand initiatives on track.

Real-Life Applications: Using Metal Tags for Diverse Branding Needs

Tags in Retail: Enhancing Product Appeal and Information

In retail settings, metal tags serve a dual purpose functionality and branding. They enhance the aesthetic appeal of products while conveying essential information such as pricing, care instructions, and product specifications. Retail advantages include the ability to evoke a sense of premium value; consumers are often willing to pay more for products adorned with high-quality metal tags. Furthermore, attractive metal tags can also enhance the overall presentation of a product, catching the attention of potential customers. For brands looking to elevate their retail presence, custom metal tags can be an effective marketing tool, allowing for unique styles that resonate with target demographics. Whether displayed on clothing, home goods, or luxury items, these tags enhance the storytelling aspect of a product, adding another layer of allure that can draw consumers in.

Creative Uses for Events and Promotions: Stand Out at Every Occasion

Metal tags are incredibly versatile and find numerous applications in events and promotions. They can serve as unique name tags, commemorative pieces, or engaging marketing items that make lasting impressions. For events such as trade shows or corporate gatherings, metal tags can be customized with attendee names and branding elements, offering not only identification but also fostering networking opportunities. Additionally, as promotional giveaways, they can function as stand-out items that keep a brand front of mind long after the event is over. Tags can be crafted as keychains, bottle openers, or decorative elements for other merchandise, thereby reinforcing brand identity through utility. Their enduring nature ensures that they remain in circulation, continually promoting the brand with every glance.

Beyond Branding: Practical Applications for Asset Management

Beyond their traditional branding roles, metal tags are indispensable tools for asset management. Many companies utilize durable custom tags for labeling equipment, tools, and inventory, enhancing organization and traceability. Metal tags can be encoded with barcodes or QR codes, allowing for easy scanning and data management, which is crucial for tracking assets across multiple locations. This application ensures that organizations can maintain accurate records and streamline inventory processes while minimizing losses due to misplacement. Furthermore, the durability of metal tags means that they can withstand tough environments without deterioration, ensuring that asset information remains intact. Switching gears from marketing to functionality, metal tags have proven valuable in enhancing operational efficiency and visibility in various industries.

Discover inspiring insights to spark your curiosity and drive.