The Intricacies of Battery Manufacturing: Powering the Future

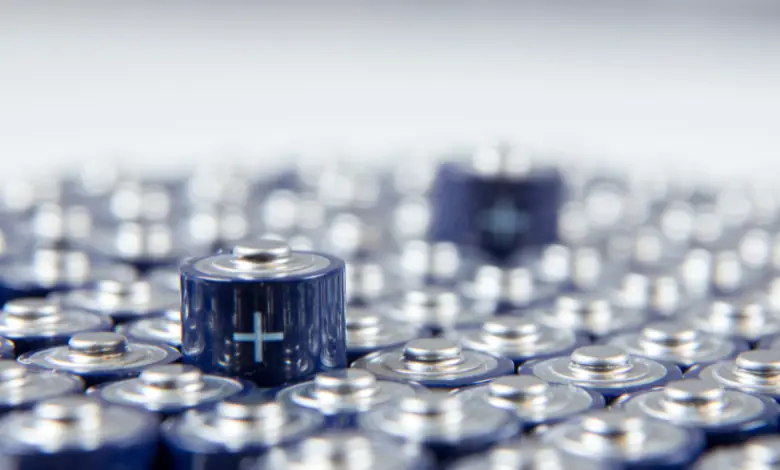

Batteries have become an integral part of our daily lives, powering everything from our smartphones to electric vehicles. However, the intricate process of manufacturing batteries is often overlooked. This blog will delve into how batteries are made, exploring the fascinating journey from raw materials to the powerful energy storage devices we rely on.

Raw Materials: The Building Blocks

The foundation of any battery lies in its raw materials. The most common types of batteries, such as lithium-ion batteries, rely on key components like lithium, cobalt, nickel, and graphite. These materials are sourced from various locations globally, and their quality significantly influences the performance and efficiency of the final product.

Sourcing High-Quality Materials: A Cornerstone for Durability and Efficiency

The quest for durability and efficiency begins with a critical emphasis on sourcing high-quality materials. The selection of top-notch components lays the foundation for creating products that not only withstand the test of time but also deliver optimal performance. One key aspect of this sourcing strategy involves establishing partnerships with reliable suppliers. A prime example is the collaboration with a stainless steel strip supplier. This strategic alliance contributes significantly to the overall quality of the energy storage devices by providing a sturdy and corrosion-resistant material. Such partnerships underscore the industry’s commitment to ensuring that every facet of the manufacturing process aligns with the highest standards, ultimately resulting in robust and efficient energy storage solutions.

Extraction and Processing

Once the raw materials are secured, the extraction and processing phase begins. Lithium, for instance, is commonly extracted from salt flats, while cobalt and nickel may come from mining operations. These materials undergo a series of chemical processes to purify and prepare them for battery production. This phase requires careful attention to environmental and ethical considerations, as some materials, like cobalt, have raised concerns about the conditions under which they are mined.

Cathode and Anode Manufacturing

The cathode and anode are the heart of a battery, responsible for storing and releasing energy during the charging and discharging cycles. Typically composed of metal oxides, the cathode is constructed using a combination of lithium, cobalt, nickel, and manganese. On the other hand, the anode, often made of graphite, plays a crucial role in facilitating the movement of ions within the battery.

Electrolyte Preparation

The electrolyte is a conductive solution that allows the flow of ions between the cathode and anode, completing the electrical circuit. The electrolyte usually consists of a lithium salt dissolved in a solvent in lithium-ion batteries. Ensuring the correct composition and purity of the electrolyte is vital for the battery’s overall performance and safety.

Cell Assembly

The battery cells are assembled once the cathode, anode, and electrolyte are prepared. This involves stacking the components in precise layers, with separators to prevent short circuits. The assembly process is carried out in controlled environments to minimise contamination and maintain the integrity of the battery.

Encapsulation and Sealing

The battery cells are encapsulated and sealed to protect the delicate internal components from external factors. This step involves carefully enclosing the cells in a metal or plastic casing and sealing it to prevent leaks. The quality of this sealing process is critical to ensuring the longevity and safety of the battery.

Testing and Quality Control

Before batteries reach consumers, they undergo rigorous testing to ensure they meet strict quality standards. Performance, capacity, and safety tests are conducted to identify any defects or inconsistencies. Only batteries that pass these tests proceed to the next stage, ensuring that only reliable and safe products make it to the market.

Packaging and Distribution

Once the batteries pass quality control, they are packaged and prepared for distribution. Packaging materials are chosen to provide additional protection during transportation and storage. The batteries are then distributed to manufacturers of various electronic devices or integrated into energy storage systems for renewable energy applications.

Conclusion

The journey from raw materials to a fully functional battery is a complex and intricate process that involves careful consideration of materials, ethical sourcing, precise manufacturing, and rigorous quality control. As our reliance on batteries continues to grow, understanding the ins and outs of their production becomes increasingly important. By appreciating the complexity of battery manufacturing, we can better grasp the technological advancements driving the energy storage industry and the pivotal role batteries play in powering our modern world.

Explore more insights and discoveries – your journey doesn’t end here, check out for a deeper dive into the fascinating world of possibilities.